CONFAB is suitable for processing of Natural, Synthetic Fiber and their blends in from of yarn and fiber.

compact designed 90° Elbow flow reversal device combined with intergrated heat exchanger and Centrifugal pump, Achieves low liquor Ratio

to1:3-6.

CONFAB can fulfill yarn dyeing in Package, Hank, Loose Fiber, Zipper, Beam, Cake form etc. When change different yarn Carrier.

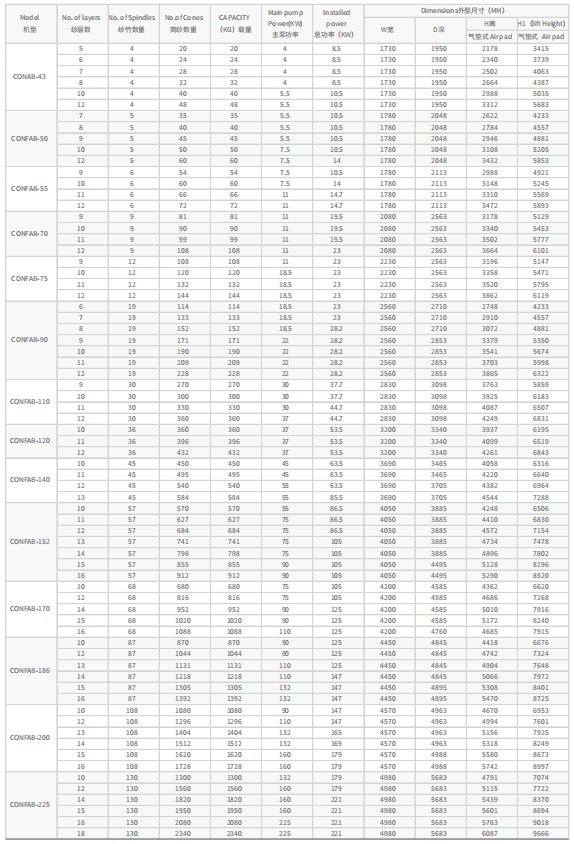

TECHNICAL DATA

Model:CONFAB

Liquor Ratio: 1:3-6

Designed Temp:140°C

Designed Pressure: 4.5Mbar

Working Pressure: 4bar

Heating Rate:25°C-130°C,average5°C/min

Cooling Rate: 130°C-80°C, average2.5°C/min

Carrier

Can carrier for hank yarn, muffs or loose fibers.

Basket carriers for loose fibers.

Carrier for beams and tapes.

Hank Yarn Carrier.

Cone / Tube / Spindle.

Bottom Disc

1.Fits perfectly with the spindle.

2.Stops leakage between bottom disc and spindle.

3.With guiding sleeve, bottom disc is always at right angle with the spindle.

4.When pressing, pressure is distributed over the package in radial direction.

5.Density of package is more even.

6.Improvied dyeing quali.

Leak Proof Fastener

1.Stops leakage between top disc and fastener.

2.Increase more effective circulation.

3.Increase efficiency of main pump,

reduces power consumption.

4.Improves package quality.

Variable Loading Capacity

1.Perforated Spindle tube is sectional type design

2.Remove upper to reduce loading of cones, no

dummy cone is required.

3.Flexible loading from 6-15layers.

Follow Down Fastener

Top and bottom plates are pressed against the package, the density at the edges are same as the

column itself.