1. Product introduction

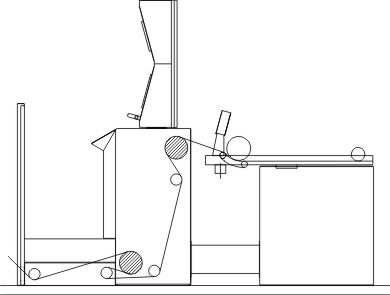

1-CLOTH INLET

1.1-Short controlled fabric guidance for optimum feeding of even extremely delicate knitted fabrics. Uniform pinning by twodriven draw rollers in the infeed unit.Infeed track lengths Up to 6 meters to take auxiliary equipment;e.g.,selvedgegumming device,steaming unit etc.

For knits:1 correction roller and 1 scroll roller

For woven: 2 guide rollers

For knits:2 correction rollers and 2 scroll rollers

1.2- Stable Positive Tension control for fabric loading.

1. 3- Precision Centering device.

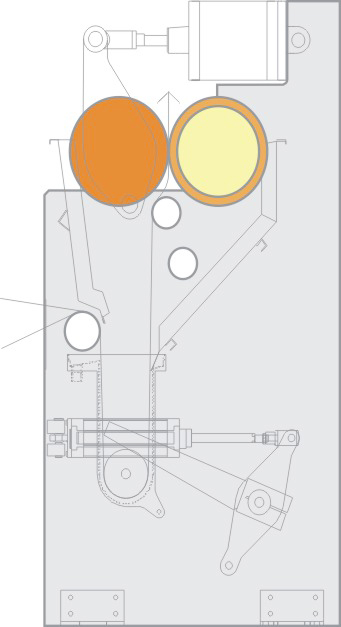

2-FINISHING PADDER

2.1-Padder Standard

Two bowl pad mangle, suitable for finishing and dehydration processes. One squeeze roller is a cylindrical and solid core roller, The other is designed as a solid core pressure roller with a crown to apply uniform pressure.

2.2-On padders with automatic quick cleaning, the trough is supplied with a system for quick draining and quick cleaning.

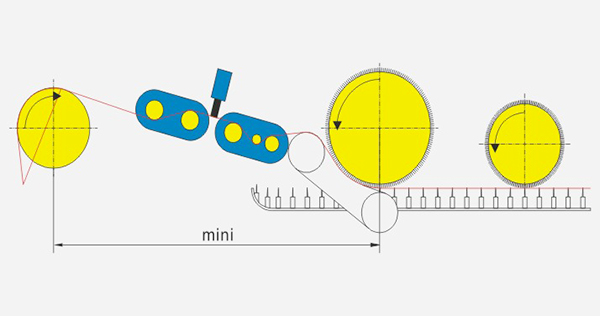

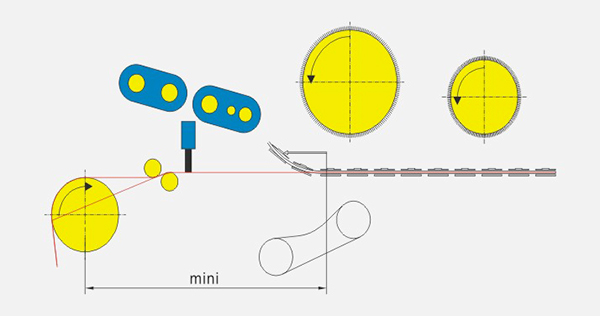

3-PINNING ON,OVERFEED AREA

3.1-Large overfeed pinning adjustment range(-10%to+60%) to accommodate the various amounts of shrinkage encountered for different fabrics.

The selvedge tension can be set separately for the left-hand and right-hand sides control.

3.2-Fabric Run:Overfeed during fabric pinning

3.2-Fabric Run:Clip operation

3.3-Stable Chain Pinning on System

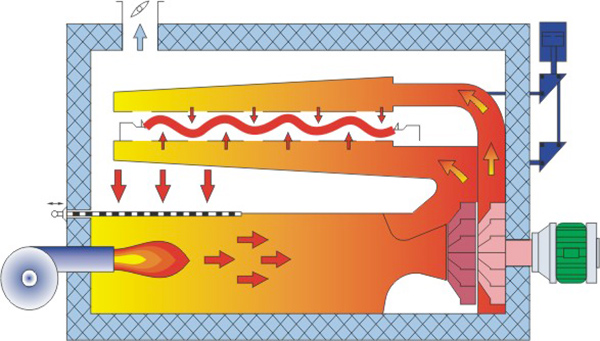

4-TREATMENT CHAMBER

|

|

4.1-10years maintenance free Chain Guide Rail (oil free)

4.2-Oil drop Removed energy saving and heat recover exhaust tunnel

4.3-Gas / Thermal Oil / Steam Heating are available.

4.4-High efficiency circulation blower

4 . 5 -Special Heat isolation material, 150mm Isolation doors.

4 . 6 -PID temperature, accuracy control up to 0.1°C

4.7-Nozzle bypass gate

1.Nozzles closed automatically.

2.Avoid air blowing to fabric when machine stops.

Normal working state

When the bypass gate is working

5-UNLOADING AREA

5 . 1- Air cooling zone before unloading

5 . 2- Humidifier is for optional

5 . 3-Stable Layout device

5 . 4- Ionization device

5.5-BTA edge cutting device

Famous Eherd+Leimer BTA edge cutting device equipped with convenient gumming device and big capacitystainless steel trough. Suitable for almost all kinds offabric.

Fabric loss minimized!

6,ELECTRIC CONTROL PANEL

1.Completely Innoance Servo control system are applied in Tension, Sychronization,Width adjustment system, easy commmissioning, stable and precision running.

2.Simple and clear hardware distribution, for easy operation and maintenance.

3.CABUS communication are applied for stable communication and greatly reduced pannel space, avoid over heat from the pannel.

4.Aviation wiring plugs are applied for easy installation, commissioning, and maintenance.

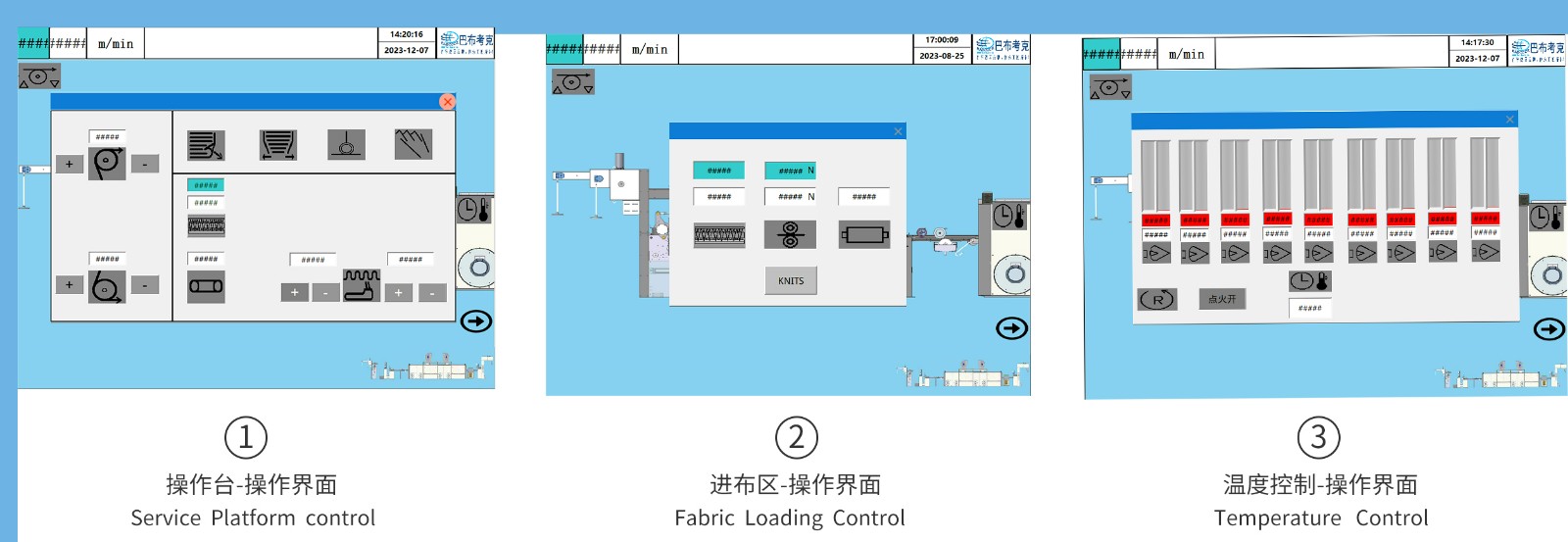

7,SOFTWARE INTERFACE

1,Interface

Simple identification symbols are reasonable arranged in the interface, even learner in the first stage can easily apply.

A,Service Platform Control

B,Fabric Loading Control

C,Temperature Control

2、Background Control System

A,The System Starts And Runs

B,Program Segment Monitoring

C,File Management Interface

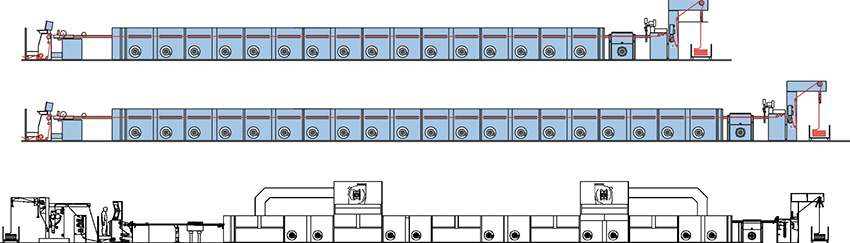

MODULAR TECHNOLOGY

Standard Version 4F-12F

Universal stenter for drying and heat setting processes. With the corresponding configuration the machine can be used for all

types of fabrics.

Stenter range for

1.Dehydration

2. Finishing

3. Drying

4. Curing

5. Heat-setting of woven and knitted fabrics

Technical data

General executions available:

1. For woven fabrics

2. For knitted fabrics

3. For woven and knitted fabrics

4. Nominal width available:180cm~380cm

5. Minimum working width:60cm

6. Number of chambers available:4~12

7. Max.chamber temperature:230°C

8. Stenter chains:Hercules-horizontal chain with

long term lubrication

9. Machine speeds:

2.5~50m ; 5~100m ; 7.5~150m

Working Width(mm) | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | 3200 |

Compartment | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

Installed Power(kw) | 144 | 160 | 175 | 190 | 205 | 221 | 236 | 252 | 267 |

Dimension L*W*H(m) | 31*4*3.4 | 34*4.2*3.4 | 37*4.4*3.4 | 40*4.6*3.4 | 43*4.8*3.4 | 46*5*3.4 | 49*5.2*3.4 | 52*5.4*3.4 | 55*5.6*3.4 |

Speed Range(m/min) | 5-100 | ||||||||

Heating Methods | Ⅰ:Oil heating;Ⅱ:Gas Burner;Ⅲ:High Pressure Steam | ||||||||