WINBOX is an innovative water flow dyeing machine suitable for pre-treatment,dyeing,after treatment of fabric in rope form.

◇ Extra low liquor ratio,1:3-4.5 for normal active dyeing,water consumption is Between 25-45L per kg fabric(from Light to Dark Color)

◇ Even-flow system makes the dyeing liquid circulating in horizontal manner during processing,which increased 300% circulation ratio.

◇ Even-flow dosing system to ensure consistence of dyeing liquor when contact fabric through the pressure modulation nozzle to avoid un-even dyeing.

◇ Minimized Lifting Height design ensures minimum fabric tension during processing.it is most important for the size stable of sensitive fabric like Lycra,Spandex,Viscose Modal after dyeing.

◇ Typical Processing time can be 4.5-5hours.

Because of saving compare with conventional Dyeing machine:

◇ Chemicals Auxiliaries saving 40-50%;

◇ Dyes saving 5-10%;

◇ Sewage reducing 60%;

◇ Water,Steam saving 50%;

◇ Electricity Power saving 50%.

TECHNICAL DATA

Liquor Ratio: 1:3-5

Max.Lifting speed: 500M/Min

Designed Temperature: 140℃

Designed Pressure: 3.5Mbar

Heating Gradient: 5℃/Min.form 25℃-100℃ ; 2.5℃/Min.form 100℃-130℃

Cooling Gradient: 3℃/Min.form 130℃-100℃ ; 2℃/Min.form 100℃-85℃

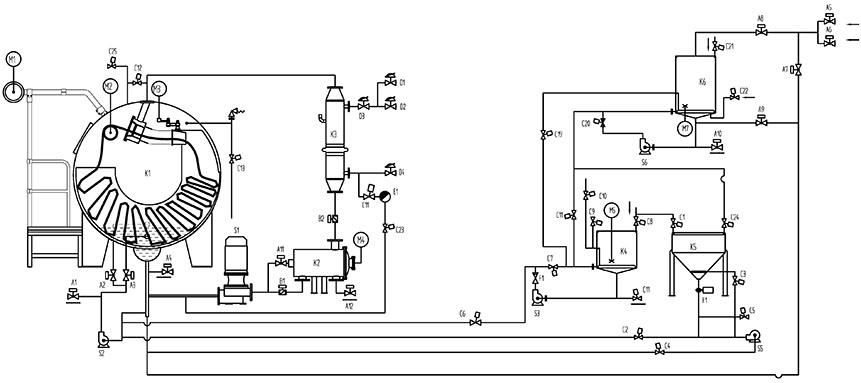

K1, Main Kier K2, Filter K3, Heat Exchanger K4. Dosing Tank K5, Salt Dosing Tank K6, Storage Tank

S1, Main Pump S2, Circulation Pump S3, Dosing Pump S5, Salt Dosing Pump S6, STK Dosing Pump

MODEL | CAPACITY(KG) | MAIN PUMP POWER (KW) | INSTALLED POWER (KW) | DIMENSIONS (MM) | ||

Length | Width | Height | ||||

WP-HT-1T200 | 200 | 7.5 | 18.8 | 3300 | 5100 | 3100 |

WP-HT-1T250 | 250 | 7.5 | 18.8 | 3500 | 5100 | 3100 |

WP-HT-2T250 | 500 | 15 | 29 | 4300 | 5300 | 3100 |

WP-HT-3T250 | 750 | 18.5 | 36 | 5600 | 5400 | 3100 |

WP-HT-4T250 | 1000 | 22 | 41.3 | 7500 | 5800 | 3100 |

WP-HT-6T250 | 1500 | 18.5*2 | 63.5 | 10000 | 5800 | 3100 |